Understanding how a Flanged Y Strainer connects into a piping system is as important as choosing the right size and screen mesh. L...

READ MOREZhejiang Xiongxiang Valve Co., Ltd. was established in 2017 and is located in Wenzhou City, Zhejiang Province, with convenient transportation. It is a company specializing in the production of valves and filters.

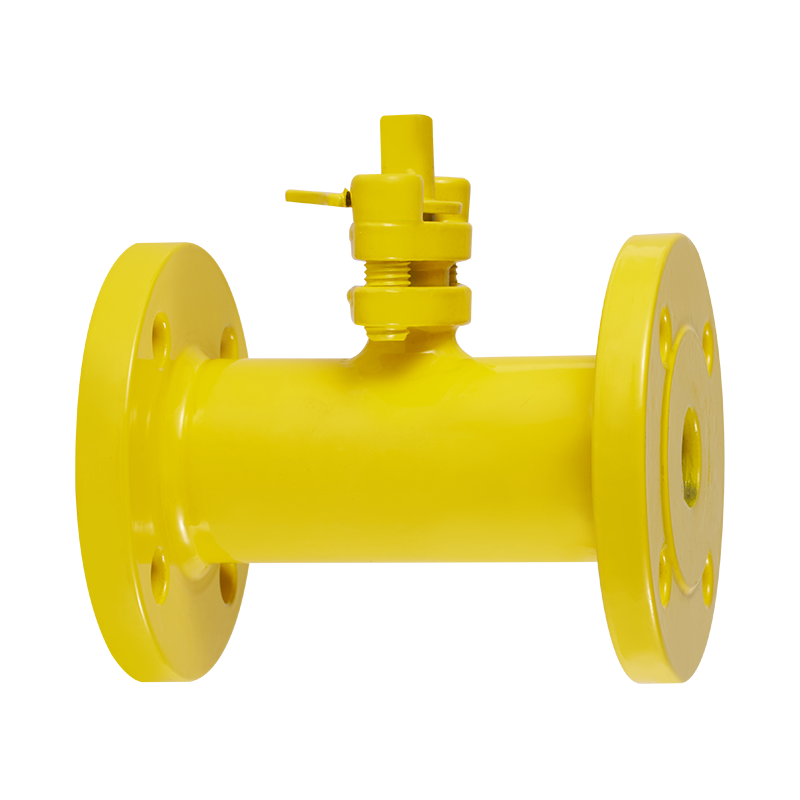

Cast Steel Ball Valve Manufacturer

Our ball valves are highly applicability and meet the high performance, reliability and safety standards of many industries. Let me walk you through the complexity of our ball valve products.

Advantages of Ball Valves

1. Reliability and Durability

Ball valves are known for their high reliability and durability, which is crucial for maintaining a consistent flow in various industrial processes. This durability enhances their applicability across different sectors.

2. Sealing Efficiency

The sealing surfaces of ball valves are designed to provide a tight seal, preventing leaks and ensuring the safety of the system. This sealing efficiency is a key factor in their broad applicability in industries where fluid containment is critical.

3. Low Friction Operation

The ball within a ball valve rotates on a spherical surface, which reduces friction compared to other valve types. This low friction operation increases the applicability of ball valves in high-pressure systems where friction can lead to wear and tear.

4. Versatility in Flow Control

Ball valves can control flow in both directions, making them highly versatile and applicable in systems that require bidirectional flow control.

5. Compact Design

The compact design of ball valves saves space, which is particularly beneficial in applications where space is at a outstanding, thus increasing their applicability in confined areas.

6. Ease of Maintenance

High-quality ball valves are designed for ease of maintenance, with replaceable seats and seals. This feature enhances their applicability in environments where regular maintenance is required.

7. High-Pressure Resistance

Ball valves are capable of withstanding high pressures, making them applicable in high-pressure applications such as oil and gas pipelines.

8. Corrosion Resistance

Many ball valves are made from materials that are resistant to corrosion, which broadens their applicability in corrosive environments, such as chemical processing plants.

Applications of Ball Valves

1. Oil and Gas Industry

Ball valves are widely used in the oil and gas industry due to their ability to handle high pressures and corrosive fluids. Their applicability in this sector is further enhanced by their resistance to harsh environmental conditions.

2. Chemical Processing

In chemical processing, ball valves are chosen for theirCorrosion resistance and sealing efficiency, making them applicable in handling aggressive chemicals.

3. Water and Wastewater Treatment

Ball valves are applicable in water and wastewater treatment plants due to their ability to control flow precisely and withstand the corrosive nature of some wastewater.

4. Power Generation

In power generation plants, ball valves are used for their high-pressure resistance and quick operation, making them applicable in controlling steam and water flow.

5. Food and Beverage Industry

The hygienic design and ease of maintenance of ball valves make them highly applicable in the food and beverage industry, where cleanliness and sanitation are important.

6.Pharmaceutical Industry

Ball valves are applicable in the pharmaceutical industry due to their ability to handle a variety of fluids, including those that are sensitive to contamination.

In conclusion, the applicability of ball valves is vast, spanning across numerous industries due to their high-quality design, durability, and versatility. Whether it's controlling flow in a high-pressure oil pipeline or ensuring a leak-free operation in a pharmaceutical facility, ball valves stand out as a reliable choice for fluid control.

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

If you are interested in any of our products or have the intention to order, please feel free to contact us.

-

-

Proper installation plays a crucial role in the performance of industrial strainers. A Cast Steel Y Type Strainer and a Flanged Y ...

READ MORE -

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipm...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installatio...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANS...

READ MORE

English

English 中文简体

中文简体