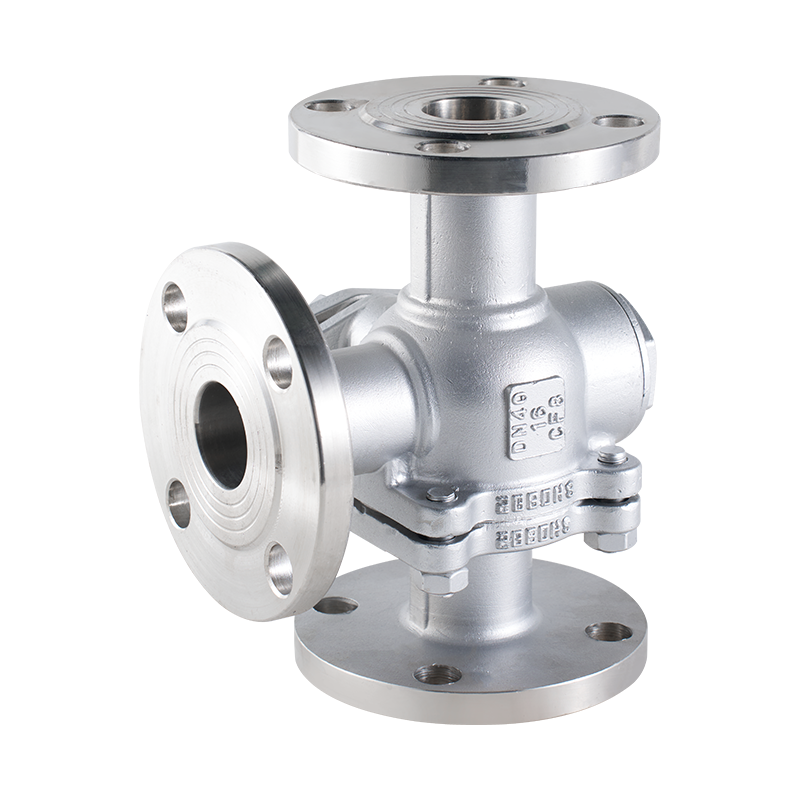

The T-type Three Ways Cast Steel Flange Ball Valve is an innovative piece of industrial equipment designed for precise control of fluid flow in various applications. This valve stands out due to its unique T-type design, which allows for the distribution or mixing of different fluids in a controlled manner.

T-type Three Ways Cast Steel Flange Ball Valve

1. Design and Construction:

The T-type Three Ways Cast Steel Flange Ball Valve is constructed with a cast steel body, which provides outstanding strength and durability. The flanged ends facilitate easy installation and ensure a secure connection to the pipeline system. The T-type design allows for three-way flow control, making it ideal for applications where分流 or mixing of fluids is required.

2. Versatility:

One of the key selling points of this valve is its versatility. It can be used in a variety of applications, including but not limited to:

- Dividing a single flow into two separate flows.

- Mixing two different flows into one.

- Redirecting flow from one path to another.

This versatility makes it a valuable asset in industries such as chemical processing, oil and gas, food and beverage, and pharmaceuticals, where precise control of fluid dynamics is crucial.

3. Operation and Maintenance:

The quarter-turn operation of the T-type Three Ways Cast Steel Flange Ball Valve makes it easy to use, even in situations where space is limited. The valve can be manually operated or automated, depending on the specific requirements of the application. Maintenance is also simplified due to the valve's design, which allows for easy access to internal components for cleaning or replacement.

4. Material and Corrosion Resistance:

The cast steel construction of the valve provides good resistance to corrosion, making it suitable for use with a wide range of fluids, including those that are aggressive or corrosive. This resistance to corrosion extends the valve's lifespan and reduces the need for frequent replacements or repairs.

5. Pressure and Temperature Ratings:

The T-type Three Ways Cast Steel Flange Ball Valve is designed to handle high pressure and temperature variations, making it suitable for use in demanding industrial environments. The specific pressure and temperature ratings will depend on the valve's size and the materials used in its construction.

6. Sealing and Leakage Prevention:

The valve's sealing mechanism is designed to prevent leakage, ensuring that fluid flow is controlled effectively and that there is no loss of product. This is particularly important in industries where even small amounts of leakage can have significant financial or environmental implications.

7. Safety and Compliance:

The valve is designed to meet or exceed industry safety standards and regulations. This ensures that it can be used in a wide range of applications without compromising on safety.

In conclusion, the T-type Three Ways Cast Steel Flange Ball Valve is a robust and versatile piece of equipment that offers a high level of control over fluid flow. Its durability, ease of operation, and customization options make it an good choice for a wide range of industrial applications. Whether you're looking to control the flow of a single fluid, mix different fluids, or redirect flow, this valve has the capabilities to meet your needs.

Main Parts Materials

| Part name | Material name | |

| GB | ASTM | |

| Valve body | WCB | A216-WCB |

| Sealing ring |

PTFE、Para-polyphenylene |

|

| Ball body | 1Cr18Ni9Ti | SS 304 |

| Valve seat, Valve stem | 2Cr13 | A246-416 |

| Stud bolts | 35CrMoA | A193-B7 |

Performance Specifications

| Nominal pressure(MPa) | Experimental pressure | |||

| Shell | High-pressure liquid seal | Pressure gas seal | ||

| 1.6 | 2.4 | 1.76 | 0.6 | |

| 2.5 | 3.75 | 2.75 | ||

| 4.0 | 6.0 | 4.4 | ||

| CLASS150 | 3.0 | 2.2 | ||

| Applicable working conditions | Applicable medium | Water, oil, gas and other non-corrosive media and acid-base corrosive media | ||

| Applicable temperature | -28~350℃ | |||

| Application specifications | Connection flange | JB79-59、GB9113、HG20592-97、ANSIB16.5 | ||

| Inspection test | GB/T9092、API598 | |||

| The rest of the manufacturing specifications are in accordance with our factory standards. | ||||

Main dimensions and connection dimensions (mm)

| Nominal pressure or pressure level | Main dimensions | Nominal diameter(mm/in) | |||||||||||

| 15/1/2" | 15/3/4" | 25/1" | 32/11/4" | 40/11/2" | 50/2" | 65/21/2" | 80/3" | 100/4" | 125/5" | 150/6" | 200/6" | ||

|

PN1.6MPa PN2.5MPa PN4.0MPa Class 150 |

L | 150 | 150 | 180 | 200 | 220 | 240 | 260 | 280 | 320 | 380 | 440 | 50 |

| L1 | 75 | 75 | 90 | 100 | 110 | 120 | 130 | 140 | 160 | 190 | 220 | 275 | |

| H | 90 | 90 | 102 | 115 | 135 | 140 | 155 | 185 | 210 | 275 | 305 | 335 | |

| W | 140 | 140 | 155 | 250 | 250 | 350 | 350 | 420 | 700 | 1000 | 1300 | 1800 | |

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

In the future, Zhejiang Xiongxiang Valve will continue to uphold the concept of "quality-oriented, customer first", continue to innovate, work together with global partners for win-win results, and create a trustworthy fluid control brand!

-

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipment within...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installations that ex...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANSI Globe Va...

READ MORE -

When planning a new industrial piping project, buyers and engineers often look to SS globe valve manufacturers for quotes and performance sp...

READ MORE -

When evaluating SS globe valve manufacturers for a new fluid control project, engineers and procurement teams often raise questions about ho...

READ MORE -

Understanding the differences between a cast steel ball valve and its flanged variants is crucial for safe and efficient pipeline operation....

READ MORE

English

English 中文简体

中文简体