Understanding the differences between a cast steel ball valve and its flanged variants is crucial for safe and efficient pipeline operation. Partnering with experienced flanged ball valve suppliers such as Zhejiang Xiongxiang Valve Co., Ltd. ensures access to high-quality valves, expert guidance, and customized solutions.

1. Structural Differences and Design Features

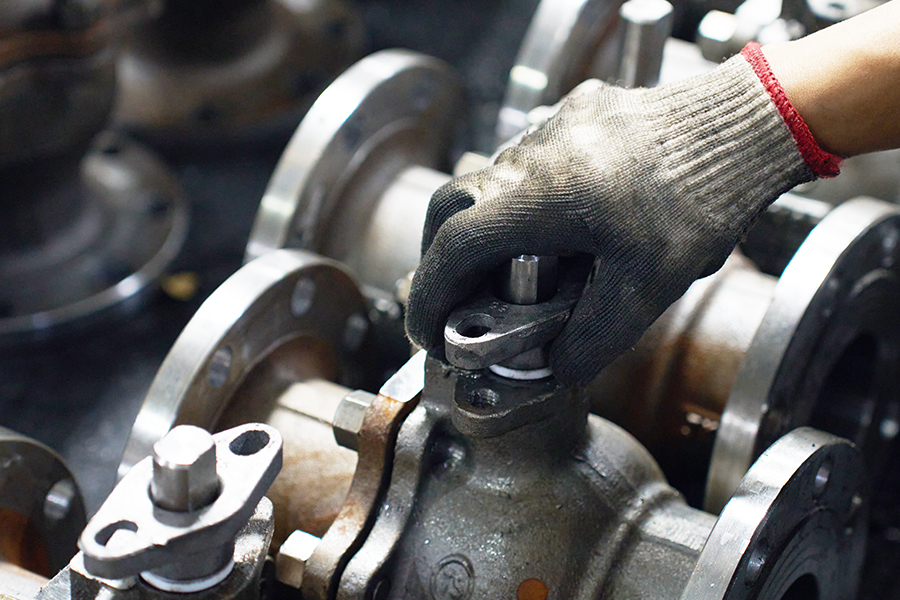

Cast Steel Ball Valve: Constructed from cast steel, this valve uses a spherical ball that rotates within the valve body to regulate flow. Its design offers strong mechanical performance, reliable sealing, and durability in high-pressure pipelines.

Flanged Ball Valve: Flanged refers to the connection type rather than the material. Flanged valves have bolted flange ends, providing secure pipeline attachment and easier installation and maintenance.

Combination of Features: Many cast steel ball valves come with flanged ends, combining material strength with easy installation, leak prevention, and maintenance convenience.

Valve Variants: Depending on application requirements, valves can be full-bore, reduced-bore, or trunnion-mounted, each offering specific flow characteristics and pressure handling capabilities.

2. Performance Considerations

Pressure Handling: Cast steel ball valves are suitable for high-pressure systems, often used in petrochemical and oil & gas pipelines. Flanged connections enhance structural integrity and leak resistance.

Temperature Resistance: Cast steel handles high and low temperatures effectively. Paired with proper flange and seat materials, these valves maintain reliability under varying conditions.

Sealing and Flow Control: Spherical ball design ensures tight sealing. The flanged connection allows for consistent installation, minimizing leaks and ensuring predictable flow rates.

3. Application Scenarios

Petrochemical Pipelines: High-pressure crude oil and gas pipelines benefit from the durability and reliable sealing of cast steel flanged ball valves.

Water Treatment Systems: Precise flow control and reliable shut-off are essential; the combination of cast steel strength and flanged connection makes maintenance easier.

Power Plants: Steam, cooling water, and chemical systems require valves that can withstand temperature fluctuations and high pressure.

Chemical Processing: Resistance to corrosion and abrasive fluids makes these valves suitable for aggressive chemical environments.

4. Choosing the Correct Supplier

Quality Assurance: Reliable flanged ball valve suppliers ensure valves meet ISO standards and undergo rigorous testing for pressure, leakage, and material integrity.

Customization: Suppliers can provide valves tailored to specific pressures, sizes, and flange standards, ensuring compatibility with pipeline systems.

Technical Support: Trusted suppliers like Zhejiang Xiongxiang Valve Co., Ltd. provide guidance on valve selection, installation, and maintenance to prevent operational issues.

Availability: Timely delivery and stock availability are important for project schedules and operational continuity.

5. Maintenance and Operational Recommendations

Regular Inspection: Check for wear, corrosion, and leakage around flanges, stems, and seats, especially in high-pressure or chemically aggressive systems.

Proper Operation: Avoid rapid opening or closing of valves in pressurized systems to reduce stress and prevent water hammer.

Seat and Seal Replacement: Replace seats and gaskets as needed to maintain sealing performance and prevent operational failure.

Lubrication and Cleaning: Periodic lubrication and cleaning of moving parts ensure smooth operation and prolong valve life.

Record Keeping: Maintaining a detailed maintenance log helps track performance, anticipate failures, and plan preventive maintenance.

6. Buyer Tips for good Selection

Evaluate Operating Conditions: Consider fluid type, pressure, temperature, and flow rate to determine valve size, material, and connection type.

Check Standards Compliance: Ensure valves comply with international or project-specific standards for flanges, materials, and pressure classes.

Assess Supplier Expertise: Working with knowledgeable suppliers ensures access to technical guidance, quality products, and after-sales support.

Consider Lifecycle Cost: Evaluate not only the purchase price but also maintenance, operational efficiency, and durability for long-term savings.

English

English 中文简体

中文简体