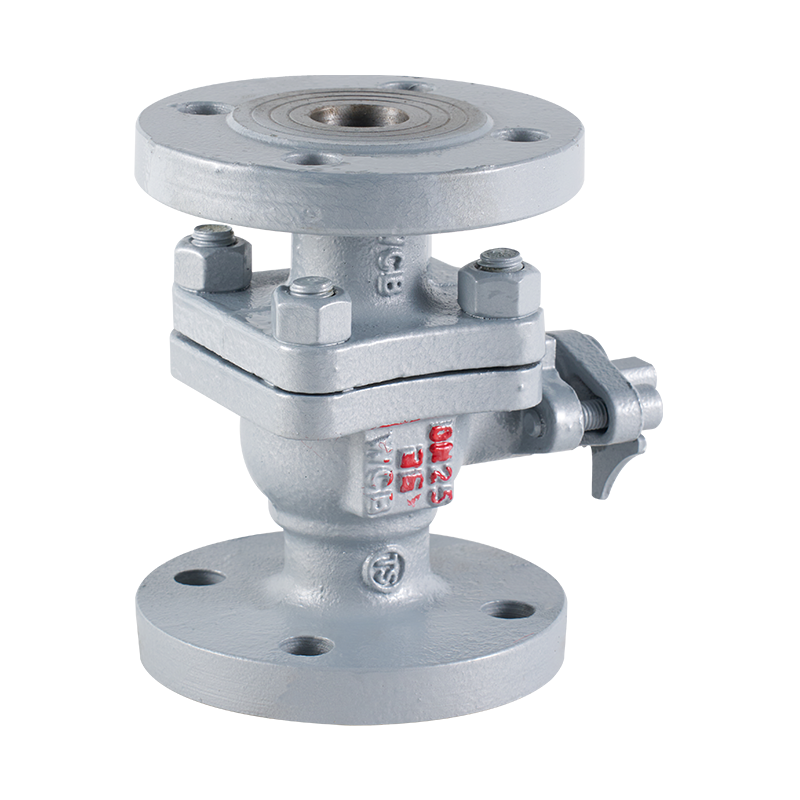

Stainless Steel Flanged Floating Ball Valves are highly regarded in the industry for their durability, reliability, and versatility. These valves are designed to handle a wide range of applications with precision and efficiency.

Stainless Steel Flanged Floating Ball Valve

1. Corrosion Resistance:

Stainless steel construction provides outstanding resistance to corrosion, making these valves suitable for use in environments where chemicals, saltwater, and other corrosive substances are present. This resistance extends the valve's lifespan and reduces maintenance costs.

2. Flanged Design:

The flanged design allows for easy installation and removal, facilitating maintenance and repair. Flanges also provide a strong, leak-proof connection to pipes, ensuring the integrity of the system.

3. Floating Ball Mechanism:

The floating ball design allows the ball to be held in place by the pressure of the fluid on both sides, which means the sealing is not dependent on the stem. This reduces the wear and tear on the valve, thus a longer service life.

4. Precision Flow Control:

These valves offer precise control over the flow of fluids, with a 90-degree rotation providing a full open or closed position. This makes them ideal for applications requiring accurate flow regulation.

5. Wide Temperature Range:

Stainless steel valves can operate effectively in a broad temperature range, from cryogenic temperatures to high-temperature applications, making them versatile for various industries.

6. Low Operating Torque:

The floating ball design reduces the operating torque required to open or close the valve, which means less energy is needed to operate the valve, reducing wear and tear on the actuator.

7. High-Quality Sealing:

Stainless Steel Flanged Floating Ball Valves often feature advanced sealing materials that provide a tight seal, preventing leaks and ensuring the safety and efficiency of the fluid control system.

8. Durability and Strength:

The combination of stainless steel and a floating ball design results in a valve that is both strong and durable. This makes them suitable for high-pressure applications where reliability is crucial.

9. Ease of Automation:

These valves are compatible with various automation systems, allowing for remote operation and integration into smart control systems, which is beneficial for modern industrial processes.

10. Compact Design:

Despite their robust construction, Stainless Steel Flanged Floating Ball Valves are designed to be compact, saving space in installations and reducing the overall footprint of the system.

11. Cost-Effectiveness:

While the initial cost of stainless steel valves may be higher than that of other materials, their long-term cost-effectiveness is significant due to their durability, low maintenance, and energy efficiency.

12. Versatility in Applications:

These valves are used in a wide range of industries, including oil and gas, chemical processing, water treatment, food and beverage processing, and pharmaceuticals, making them a versatile choice for various fluid control needs.

13. Standardization and Compliance:

Stainless Steel Flanged Floating Ball Valves are manufactured to meet international standards and industry specifications, ensuring compatibility and compliance with safety and performance requirements.

14. Environmental Compatibility**: Stainless steel is a recyclable material, which makes these valves environmentally friendly. They do not contribute to environmental pollution and are a sustainable choice for industries looking to reduce their environmental impact.

In conclusion, Cast Steel Thermal Insulation Ball Valves offer a combination of performance, durability, and efficiency that makes them an good choice for a variety of industrial.

Performance specification

| Material name | Applicable temperature | Applicable medium |

| CF8 | ≤150℃ | Nitric Acid |

| 0Cr18Ni9 | Nitric Acid | |

| CF8M | Nitric Acid | |

| 0Cr18Ni12Mo2Ti | Nitric Acid | |

| CF3 | Nitric Acid | |

| 00Cr18Ni10 | Nitric Acid | |

| CF3M | Nitric Acid | |

| 00Cr17Ni14Mo2 | Nitric Acid |

Implementation standard

| Project | Design and production | Pressure and temperature grade |

| Standard | API 6D | ANSI B16.34 |

| Flange standard | Structural length | Inspection and test |

| ANSI B16.5 | ANSI B16.10 | API 598 |

Test pressure

| Type | Mpa | Pai |

| Strength test | 7.5 | 1125 |

| High pressure seal test (water) | 5.5 | 815 |

| Low pressure seal test (air) | 5-7 bar | |

Test pressure (API 1598)

| Type | Mpa | Pai |

| Strength test | 3.0 | 450 |

| High pressure seal test (water) | 2.2 | 314 |

| Low pressure seal test (air) | 5-7 bar | |

150Lb overall dimensions and connection dimensions (mm)

| Nominal diameter | Unit pressure level | L | D | D1 | D2 | H | b | Z-φd | D0 | |

| In | mm | |||||||||

| 1/2" | 15 | 150-Lb | 108 | 90 | 60.5 | 35 | 72 | 12 | 4-16 | 115 |

| 10-k | 108 | 95 | 70 | 51 | 72 | 12 | 4-15 | 115 | ||

| 3/4" | 20 | 150-Lb | 117 | 100 | 70 | 43 | 76 | 13.5 | 4-16 | 115 |

| 10-k | 117 | 100 | 75 | 56 | 76 | 14 | 4-15 | 115 | ||

| 1" | 25 | 150-Lb | 127 | 110 | 79.5 | 51 | 92 | 15 | 4-16 | 150 |

| 10-k | 127 | 125 | 90 | 67 | 92 | 14 | 4-19 | 150 | ||

| 11/2" | 40 | 150-Lb | 165 | 125 | 98.5 | 73 | 123 | 18 | 4-16 | 200 |

| 10-k | 165 | 140 | 105 | 81 | 123 | 16 | 4-19 | 200 | ||

| 2" | 50 | 150-Lb | 178 | 150 | 120.5 | 92 | 132 | 19.5 | 4-19 | 200 |

| 10-k | 178 | 155 | 120 | 96 | 132 | 16 | 4-19 | 200 | ||

| 21/2" | 65 | 150-Lb | 190 | 180 | 139.5 | 105 | 164 | 23 | 4-19 | 320 |

| 10-k | 190 | 175 | 140 | 116 | 164 | 18 | 4-19 | 320 | ||

| 3" | 80 | 150-Lb | 203 | 190 | 152.5 | 127 | 173 | 24.5 | 4-19 | 320 |

| 10-k | 203 | 185 | 150 | 126 | 173 | 18 | 8-19 | 320 | ||

| 4" | 100 | 150-Lb | 229 | 230 | 190.5 | 157 | 210 | 24.5 | 8-19 | 450 |

| 10-k | 229 | 210 | 175 | 151 | 210 | 18 | 8-19 | 450 | ||

| 6" | 150 | 150-Lb | 394 | 280 | 241.5 | 216 | 288 | 16 | 8-22 | 800 |

| 10-k | 394 | 280 | 240 | 212 | 288 | 22 | 8-23 | 800 | ||

| 8" | 200 | 150-Lb | 457 | 345 | 298.5 | 270 | 374 | 29 | 8-22 | 1120 |

| 10-k | 457 | 330 | 290 | 262 | 374 | 22 | 12-23 | 1120 | ||

| 10" | 250 | 150-Lb | 533 | 405 | 362 | 324 | 366 | 31 | 12-25 | 1420 |

| 10-k | 533 | 400 | 355 | 324 | 366 | 24 | 12-25 | 1420 | ||

| 12" | 300 | 150-Lb | 610 | 485 | 432 | 381 | 412 | 32.5 | 12-25 | 1420 |

| 10-k | 610 | 445 | 400 | 368 | 412 | 24 | 16-25 | 1420 | ||

300Lb overall dimensions and connection dimensions (mm)

| Nominal diameter | Unit pressure level | L | D | D1 | D2 | H | b | Z-φd | D0 | |

| In | mm | |||||||||

| 1/2" | 15 | 300-Lb | 140 | 95 | 66.5 | 35 | 72 | 15 | 4-16 | 100 |

| 20-k | 140 | 95 | 70 | 51 | 72 | 14 | 4-15 | 100 | ||

| 3/4" | 20 | 300-Lb | 152 | 115 | 82.5 | 43 | 76 | 16.5 | 4-19 | 100 |

| 20-k | 152 | 100 | 75 | 56 | 76 | 16 | 4-15 | 100 | ||

| 1" | 25 | 300-Lb | 165 | 125 | 89 | 51 | 92 | 18 | 4-19 | 140 |

| 20-k | 165 | 125 | 90 | 67 | 92 | 16 | 4-19 | 140 | ||

| 11/2" | 40 | 300-Lb | 190 | 155 | 114.5 | 73 | 123 | 21.5 | 4-22 | 200 |

| 20-k | 190 | 140 | 105 | 81 | 123 | 18 | 4-19 | 200 | ||

| 2" | 50 | 300-Lb | 216 | 165 | 127 | 92 | 132 | 23 | 8-19 | 200 |

| 20-k | 216 | 155 | 120 | 96 | 132 | 18 | 8-19 | 200 | ||

| 21/2" | 65 | 300-Lb | 241 | 190 | 149 | 105 | 164 | 26 | 8-22 | 250 |

| 20-k | 241 | 175 | 140 | 116 | 164 | 20 | 8-19 | 250 | ||

| 3" | 80 | 300-Lb | 283 | 210 | 168.5 | 127 | 173 | 29 | 8-22 | 250 |

| 20-k | 283 | 200 | 160 | 132 | 173 | 22 | 8-23 | 250 | ||

| 4" | 100 | 300-Lb | 305 | 255 | 200 | 157 | 210 | 32.5 | 8-22 | 250 |

| 20-k | 305 | 225 | 185 | 160 | 210 | 24 | 8-23 | 250 | ||

| 6" | 150 | 300-Lb | 403 | 320 | 270 | 216 | 336 | 37 | 12-22 | 350 |

| 20-k | 403 | 305 | 260 | 230 | 336 | 28 | 12-25 | 350 | ||

| 8" | 200 | 300-Lb | 502 | 380 | 330 | 270 | 385 | 42 | 12-25 | 400 |

| 20-k | 502 | 350 | 305 | 275 | 385 | 30 | 12-25 | 400 | ||

| 10" | 250 | 300-Lb | 568 | 445 | 387.5 | 324 | 370 | 48.5 | 16-29 | 450 |

| 20-k | 568 | 430 | 380 | 345 | 370 | 34 | 12-27 | 450 | ||

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

In the future, Zhejiang Xiongxiang Valve will continue to uphold the concept of "quality-oriented, customer first", continue to innovate, work together with global partners for win-win results, and create a trustworthy fluid control brand!

-

Understanding how a Flanged Y Strainer connects into a piping system is as important as choosing the right size and screen mesh. Like a Cast...

READ MORE -

Proper installation plays a crucial role in the performance of industrial strainers. A Cast Steel Y Type Strainer and a Flanged Y Strainer a...

READ MORE -

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipment within...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installations that ex...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANSI Globe Va...

READ MORE -

When planning a new industrial piping project, buyers and engineers often look to SS globe valve manufacturers for quotes and performance sp...

READ MORE

English

English 中文简体

中文简体