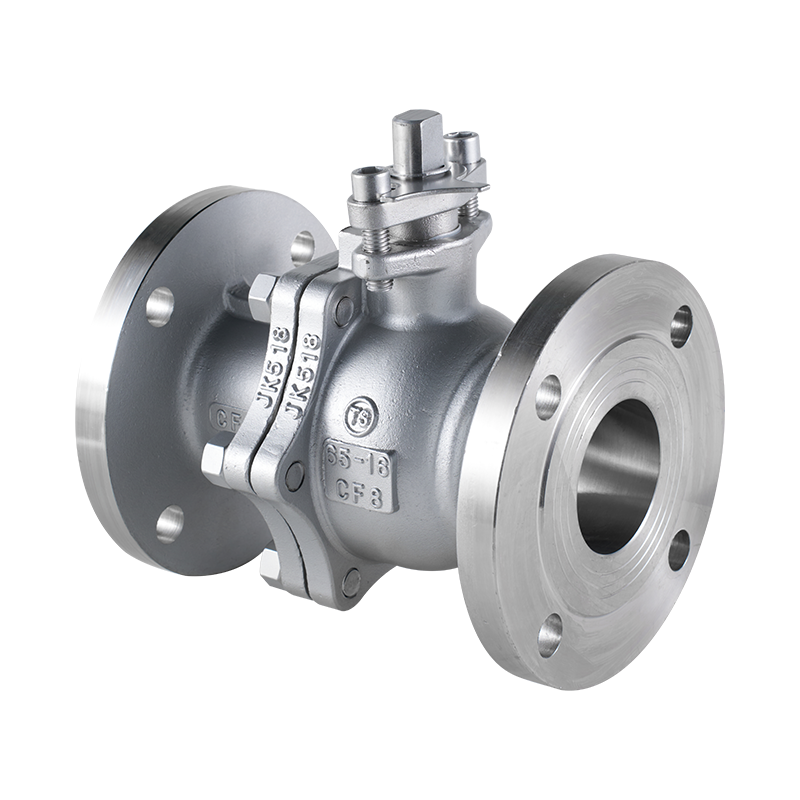

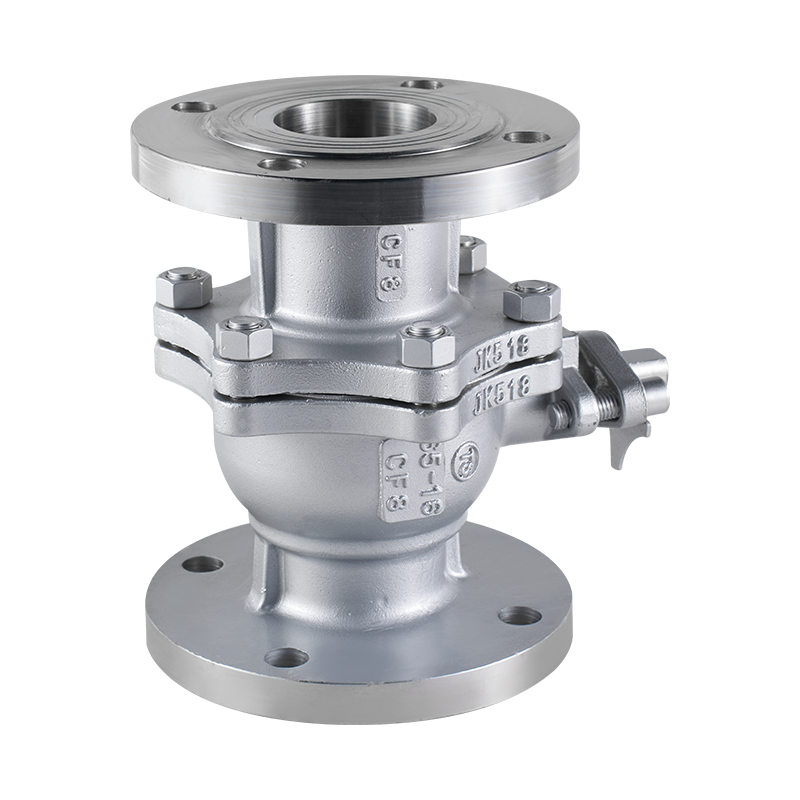

The High Temperature Material Ball Valve is a specialized type of industrial valve designed to operate efficiently in environments where high temperatures are the norm. These valves are engineered to maintain their structural integrity and functionality even when exposed to heat, making them indispensable in various industries such as petrochemical, power generation, and food processing, where high temperatures are a common challenge.

High Temperature Material Ball Valve

Advantages:

1. Durability and Longevity:

High Temperature Material Ball Valves are constructed from materials that can withstand prolonged exposure to high temperatures without losing their strength or integrity. This durability extends the valve's lifespan, reducing the need for frequent replacements and less maintenance costs.

2. Sealing Performance:

These valves are designed with advanced sealing mechanisms that maintain a tight seal even under high pressure and temperature conditions. This feature prevents leaks and ensures that the fluid being controlled remains contained, which is crucial for safety and efficiency.

3. Resistance to Corrosion:

The materials used in High Temperature Material Ball Valves are resistant to corrosion, which is a common issue in high-temperature applications where chemical reactions can lead to the degradation of valve components. This resistance protects the valve from damage and extends its service life.

4. Ease of Operation:

Ball valves are known for their straightforward operation. The quarter-turn rotation of the handle makes them easy to open and close, even in tight spaces. This simplicity reduces the risk of operator error and speeds up the process control.

5. Versatility:

High Temperature Material Ball Valves can be customized to fit a variety of applications. They can be configured with different port sizes, connection type and actuation methods to suit specific process requirements.

6. Flow Control:

The ball within the valve provides a smooth bore, which less flow restriction and turbulence. This feature is beneficial for maintaining fluid flow rates and reducing pressure drop across the valve.

7. Reliability:

The robust construction and high-quality materials used in High Temperature Material Ball Valves contribute to their reliability. They are less prone to failure, which is essential in critical processes where downtime can be costly.

Selling Points:

1. Customization:

High Temperature Material Ball Valves can be tailored to meet specific customer requirements, making them a versatile solution for a wide range of applications.

2. Quality Assurance:

These valves undergo rigorous quality control processes to ensure that they meet the hihg industry standards, providing customers with peace of mind.

3. Global Compliance:

They are designed to comply with international standards, making them suitable for use in global operations and facilitating trade across different regions.

4. Cost-Effectiveness:

While the initial investment in High Temperature Material Ball Valves may be higher than that of standard valves, their long-term cost savings due to reduced maintenance and increased durability make them a cost-effective choice.

5. Environmental Considerations:

The materials used in these valves are chosen for their low environmental impact, aligning with the sustainability goals of many industries.

In conclusion, High Temperature Material Ball Valves offer a range of advantages that make them an attractive choice for industries that require reliable and durable valve solutions in high-temperature environments. Their combination of durability, safety, and performance, along with the ability to customize and comply with global standards, positions them as a thus option in the market.

Main Parts Materials

| Part name | Material name | |

| Q41F-16P-25P-40P | Q41F-16R-25R-40R | |

| Valve body | Cr Ni Ti steel | Cr Ni Mo Ti steel |

| Ball body | ||

| Valve stem | ||

| Sealing ring | PTFE | |

| Wrench | Cast steel | |

Performance Specifications

| Type | Nominal Pressure | Test Pressure | Operating Temperature (°C) | Applicable Media | ||

| Strength (Water) (Mpa) | Sealed (Water) Air (Mpa) | Low Pressure Sealing Air (Mpa) | ||||

| Q41F-16P(R) | 16 | 2.4 | 1.76 | 0.6 | ≤150℃ | Nitric Acid |

| Q41F-25P(R) | 25 | 3.75 | 2.75 | 0.6 | ≤150℃ | Acetic Acid |

| Q41F-40P(R) | 40 | 6.0 | 4.4 | 0.6 | ≤150℃ | Nitric Acid |

Main dimensions and connection dimensions (mm)

| Type | Nominal Diameter | Dimension(mm) | |||||||

| L | D | D1 | D2 | H | b-f | z-φd | D0 | ||

| Q41F-16P(R) | 15 | 130 | 95 | 65 | 45 | 60 | 14-2 | 4-14 | 108 |

| 20 | 140 | 105 | 75 | 55 | 65 | 14-2 | 4-14 | 120 | |

| 25 | 150 | 115 | 85 | 65 | 90 | 14-2 | 4-14 | 165 | |

| 32 | 165 | 135 | 100 | 78 | 105 | 16-2 | 4-18 | 180 | |

| 40 | 180 | 145 | 110 | 85 | 150 | 16-3 | 4-18 | 240 | |

| 50 | 200 | 160 | 125 | 100 | 190 | 16-3 | 4-18 | 240 | |

| 65 | 220 | 180 | 145 | 120 | 195 | 18-3 | 4-18 | 320 | |

| 80 | 250 | 195 | 160 | 135 | 215 | 20-3 | 8-18 | 350 | |

| 100 | 280 | 215 | 180 | 155 | 250 | 20-3 | 8-18 | 400 | |

| 125 | 320 | 245 | 210 | 185 | 280 | 22-3 | 8-18 | 500 | |

| 150 | 360 | 280 | 240 | 210 | 320 | 24-3 | 8-23 | 600 | |

| 200 | 400 | 335 | 295 | 265 | 370 | 26-3 | 12-23 | 100 | |

| Q41F-25P(R) | 40 | 180 | 145 | 110 | 85 | 160 | 18-3 | 4-18 | 240 |

| 50 | 200 | 160 | 125 | 100 | 205 | 20-3 | 4-18 | 270 | |

| 65 | 220 | 180 | 145 | 120 | 215 | 22-3 | 8-18 | 350 | |

| 80 | 250 | 195 | 160 | 135 | 230 | 22-3 | 8-18 | 400 | |

| 100 | 280 | 230 | 190 | 160 | 270 | 24-3 | 8-23 | 500 | |

| 125 | 320 | 270 | 220 | 188 | 300 | 28-3 | 8-25 | 600 | |

| 150 | 360 | 300 | 250 | 218 | 340 | 30-3 | 8-25 | 900 | |

| 200 | 400 | 360 | 310 | 278 | 400 | 34-3 | 12-25 | 1100 | |

| Q41F-25P(R) | 15 | 130 | 95 | 65 | 45 | 60 | 16-2 | 4-14 | 40 |

| 20 | 140 | 105 | 75 | 55 | 65 | 16-2 | 4-14 | 51 | |

| 25 | 150 | 115 | 85 | 65 | 90 | 16-2 | 4-14 | 58 | |

| 32 | 180 | 135 | 100 | 78 | 105 | 18-2 | 4-18 | 66 | |

| 40 | 200 | 145 | 110 | 85 | 170 | 18-3 | 4-18 | 76 | |

| 50 | 220 | 160 | 125 | 100 | 230 | 20-3 | 4-18 | 88 | |

| 65 | 250 | 180 | 145 | 120 | 250 | 22-3 | 8-18 | 110 | |

| 80 | 280 | 195 | 160 | 135 | 250 | 22-3 | 8-18 | 121 | |

| 100 | 320 | 230 | 190 | 160 | 295 | 24-3 | 8-23 | 150 | |

| 125 | 400 | 270 | 220 | 188 | 330 | 28-3 | 8-25 | 176 | |

| 150 | 400 | 300 | 250 | 218 | 375 | 30-3 | 8-25 | 204 | |

| 200 | 550 | 375 | 320 | 282 | 440 | 38-3 | 12-30 | 260 | |

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

In the future, Zhejiang Xiongxiang Valve will continue to uphold the concept of "quality-oriented, customer first", continue to innovate, work together with global partners for win-win results, and create a trustworthy fluid control brand!

-

Understanding how a Flanged Y Strainer connects into a piping system is as important as choosing the right size and screen mesh. Like a Cast...

READ MORE -

Proper installation plays a crucial role in the performance of industrial strainers. A Cast Steel Y Type Strainer and a Flanged Y Strainer a...

READ MORE -

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipment within...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installations that ex...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANSI Globe Va...

READ MORE -

When planning a new industrial piping project, buyers and engineers often look to SS globe valve manufacturers for quotes and performance sp...

READ MORE

English

English 中文简体

中文简体