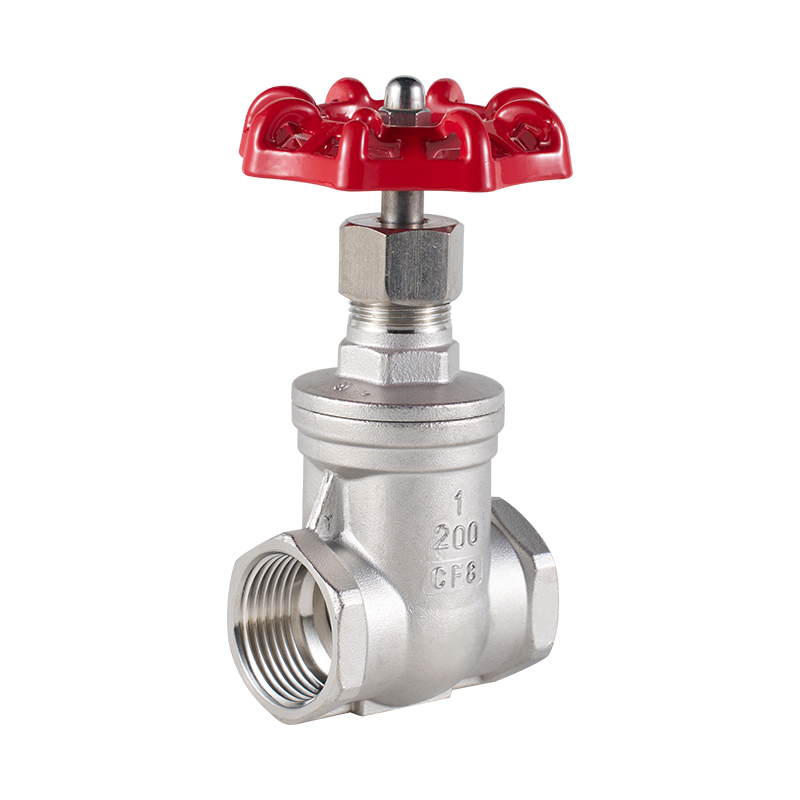

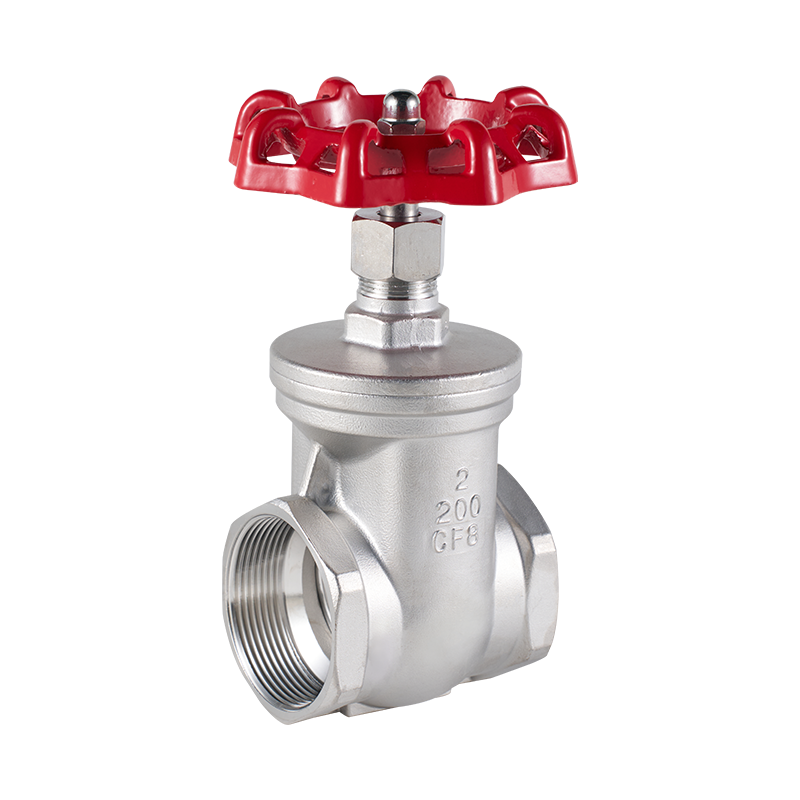

The Stainless Manual Threaded Gate Valve is a type of industrial valve that is widely used for controlling the flow of various fluids in pipelines. It is designed for applications where precise flow control and durability are essential.

Stainless Manual Threaded Gate Valve

1. Material Quality and Durability

Stainless Manual Threaded Gate Valves are constructed from high-quality stainless steel, which is known for its outstanding durability and longevity. This material is resistant to rust, corrosion, and other forms of wear and tear, ensuring that the valve maintains its integrity over time. The use of stainless steel also means that the valve can withstand harsh chemicals and high temperatures without compromising its structural integrity.

2. Threaded Connections for Easy Installation

One of the key advantages of these valves is their threaded connections, which allow for quick and easy installation. The threaded design ensures a secure fit, reducing the risk of leaks and providing a reliable seal. This feature is particularly beneficial in applications where frequent installation and removal of valves are required, as it saves time and labor costs.

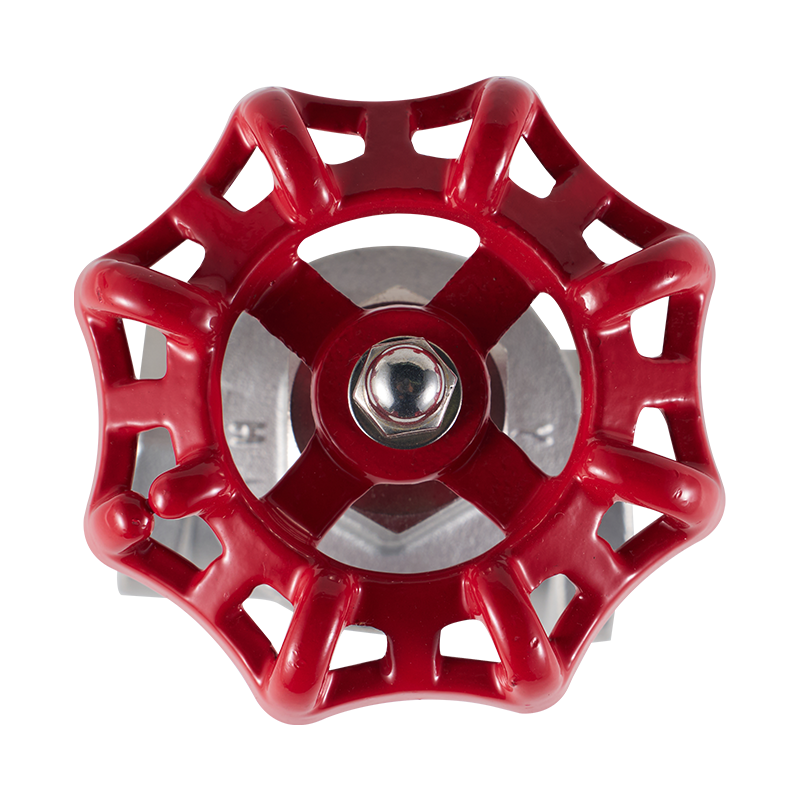

3. Manual Operation for Precise Control

The manual operation of these gate valves allows for precise control over the flow of fluids. This is particularly important in applications where precise flow control is necessary, such as in chemical processing or water treatment. The manual operation also means that these valves can be used in environments where automated systems are not feasible or practical.

4. Wide Range of Sizes and Pressure Ratings

Stainless Manual Threaded Gate Valves are available in a wide range of sizes and pressure ratings, making them suitable for a variety of applications. This versatility allows engineers and technicians to select the valve that nice fits their specific needs, whether they require a small valve for a low-pressure application or a large valve for high-pressure use.

5. Low Flow Resistance

The design of the gate valve, with its straight-through flow path, results in low flow resistance. This means that these valves can handle high flow rates without significant pressure drop, making them efficient and cost-effective for fluid control.

6. Tight Shut-Off Capability

One of the primary functions of a gate valve is to provide a tight shut-off, and the Stainless Manual Threaded Gate Valve excels in this regard. The wedge-shaped gate within the valve seat creates a strong seal, preventing fluid leakage and ensuring that the valve can be relied upon to stop flow completely when needed.

7. Corrosion Resistance

The stainless steel material used in the construction of these valves provides good corrosion resistance, making them suitable for use with a wide range of fluids, including those that are corrosive. This resistance to corrosion extends the life of the valve and reduces the need for frequent replacement or maintenance.

8. Cost-Effectiveness

Despite their high-quality construction, Stainless Manual Threaded Gate Valves are often more cost-effective than other types of valves. Their durability and low maintenance requirements mean that they represent a good investment for businesses, as they can save money in the long run by reducing the need for frequent replacements.

In summary, the Stainless Manual Threaded Gate Valve is a robust and versatile piece of equipment that is well-suited for a variety of fluid control applications. Its combination of durability, ease of use, and reliability makes it a popular choice among engineers and technicians in many industries.

| Product Name | 200WOG CF8M Stainless steel Threaded Gate Valve |

| Material | SS304/316/304L/316L ( CF8/CF8M/CF3/CF3M), WCB, etc. |

| Size | 1/2''~4'' ( DN15~DN100) |

| Thread standard | ISO9001 & CE, TS |

| Port | Full Port |

| Working Pressure | 200WOG/PSI |

| Connection Ends | NPT/BSP/BSPT/DIN259/DIN2999 |

| Working Temp. | -29~425ºC, or according to customer requirements for different industry. |

| Suitable Medium | Water, Natural Gas, Oil and some corrosive liquid |

| Operated | Handwheel |

| Inspection & Testing | According to API598 |

| Shipment | |

| Delivery Time | 15~20 Days |

| Package | Standard Exporting Plywood Case |

| Shipping Port | Ningbo/Shanghai, China |

| Shipping Terms | Exw, FOB, CFR, CIF, etc. |

| Payment Terms | T/T, Western Union, PayPal, etc. 30% prepayment, 70% balance paid before shipping or against copy of BL |

| Country of Origin | Wenzhou city, China |

| Production Capacity | 6000 ton/year |

| MOQ | 10 PCS/size |

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

In the future, Zhejiang Xiongxiang Valve will continue to uphold the concept of "quality-oriented, customer first", continue to innovate, work together with global partners for win-win results, and create a trustworthy fluid control brand!

-

Understanding how a Flanged Y Strainer connects into a piping system is as important as choosing the right size and screen mesh. Like a Cast...

READ MORE -

Proper installation plays a crucial role in the performance of industrial strainers. A Cast Steel Y Type Strainer and a Flanged Y Strainer a...

READ MORE -

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipment within...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installations that ex...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANSI Globe Va...

READ MORE -

When planning a new industrial piping project, buyers and engineers often look to SS globe valve manufacturers for quotes and performance sp...

READ MORE

English

English 中文简体

中文简体