Understanding how a Flanged Y Strainer connects into a piping system is as important as choosing the right size and screen mesh. L...

READ MOREZhejiang Xiongxiang Valve Co., Ltd. was established in 2017 and is located in Wenzhou City, Zhejiang Province, with convenient transportation. It is a company specializing in the production of valves and filters.

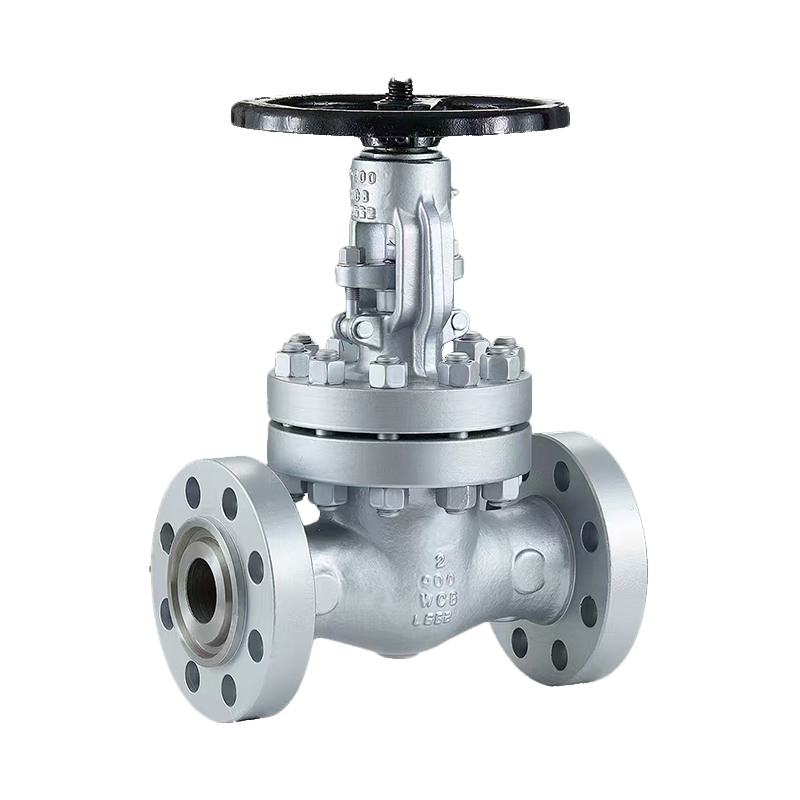

ANSI Gate Valve Factory

Gate valves are a critical component in many industrial processes, and their design and functionality offer numerous advantages that make them a top choice for various applications.Reliable and efficient gate valves are very important.

1.Advanced Design Technology:

Gate valves are designed using the new engineering technology, ensuring that they are robust and reliable. The use of advanced design software allows for precise control over the valve's dimensions and tolerances, thus a product that is highly efficient and durable.

2.High-Tech Materials:

The materials used in the construction of gate valves are selected for their technologically advanced properties. These materials, such as stainless steel and high-grade alloys, are chosen for their resistance to corrosion, high-temperature performance, and strength, which are critical technologies in ensuring the valve's longevity and reliability.

3.Precision Engineering Technology:

The manufacturing process of gate valves incorporates precision engineering technology, which ensures that each component fits goodly and operates smoothly. This technology less wear and tear, reducing the need for frequent maintenance and repairs.

4.Sealing Technology:

Gate valves are known for their superior sealing technology. The sealing surfaces are engineered to provide a tight seal, preventing leaks and ensuring that the valve can withstand high pressures. This technology is crucial in industries where leakage can lead to significant safety and environmental risks.

5.Automated Control Technology:

Many gate valves are equipped with automated control technology, allowing them to be operated remotely. This technology not only improves efficiency but also enhances safety by reducing the need for manual operation in hazardous environments.

6.Corrosion-Resistant Technology:

The application of corrosion-resistant technology in gate valves is a significant advantage. Coatings and surface treatments are applied to protect the valve from corrosive substances, which is a critical technology in environments where corrosion can lead to valve failure.

7.Pressure-Rated Technology:

Gate valves are designed with pressure-rated technology, which means they can handle a wide range of pressures without compromising their structural integrity. This technology is essential for applications where high pressures are common, such as in oil and gas pipelines.

8.Temperature-Resistant Technology:

The technology used in gate valves allows them to operate in a wide range of temperatures, from cryogenic to high-temperature applications. This temperature-resistant technology ensures that the valve maintains its performance and does not become brittle or lose its sealing properties.

9.Low Friction Technology:

Gate valves often incorporate low friction technology in their design, which reduces the amount of force needed to open and close the valve. This technology not only makes the valve easier to operate but also reduces wear and tear on the moving parts, extending the valve's lifespan.

In conclusion, gate valves offer a multitude of advantages that make them an good choice for a variety of fluid control applications. As developers, we pride ourselves on the technology and craftsmanship that go into each valve, ensuring that our customers receive a product that is not only reliable but also tailored to their specific needs. The combination of durability, tight shutoff, low friction, versatility, and technological integration makes gate valves a top choice for industries around the world.

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

If you are interested in any of our products or have the intention to order, please feel free to contact us.

-

-

Proper installation plays a crucial role in the performance of industrial strainers. A Cast Steel Y Type Strainer and a Flanged Y ...

READ MORE -

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipm...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installatio...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANS...

READ MORE

English

English 中文简体

中文简体