Cast Steel Swing Check Valves are a type of flow control device that is widely used in various industrial applications to prevent backflow or reverse flow of fluids. They are designed to open and close automatically, allowing fluid to flow in one direction while preventing backflow when the flow is stopped.

Durability and Material Strength

Cast Steel Construction: Cast steel swing check valves are made from high-quality cast steel, which provides outstanding strength and durability. This material choice ensures that the valve can withstand high pressures and temperatures, making it suitable for a wide range of applications in industries such as oil and gas, petrochemical, and power generation.

Resistant to Corrosion: The cast steel material is inherently resistant to corrosion, which is a significant advantage in environments where the valve may be exposed to corrosive fluids. This resistance extends the valve's lifespan and reduces the need for frequent replacements or repairs.

Reliable Operation

Automatic Operation: Swing check valves operate automatically, opening to allow flow in one direction and closing to prevent backflow when the flow stops or reverses. This feature ensures a reliable and consistent flow control without the need for manual intervention.

Low Head Loss: Due to their streamlined design, cast steel swing check valves offer low head loss, which means they have less impact on the flow of fluid through the system. This is particularly beneficial in applications where maintaining high flow rates is critical.

Easy Maintenance and Installation

Simple Design: The swing check valve's design is straightforward, with few moving parts, which simplifies maintenance and reduces the likelihood of mechanical failure. This simplicity also makes the valve easier to install and service.

Flanged Connections: These valves typically feature flanged connections, which are standard in the industry. This compatibility allows for easy integration with existing piping systems, reducing installation time and costs.

Versatility in Applications

Wide Range of Sizes and Pressure Ratings: Cast steel swing check valves are available in a variety of sizes and pressure ratings, making them suitable for a broad spectrum of applications. This versatility allows engineers to select the appropriate valve for specific requirements, ensuring good performance.

Applicability in Various Fluids: These valves can handle a variety of fluids, including water, steam, oil, and gases. Their ability to manage different types of media without compromising performance is a significant advantage in diverse industrial settings.

Safety and Compliance

Backflow Prevention: Swing check valves are crucial for preventing backflow, which can lead to system contamination or damage. They provide a reliable barrier that safeguards against reverse flow, ensuring the safety and integrity of the system.

Compliance with Standards: Cast steel swing check valves are manufactured to comply with international standards such as ASME, API, and ISO. This adherence to standards ensures that the valves meet the hihg quality and performance expectations.

In summary, cast steel swing check valves offer a combination of durability, reliability, and versatility that makes them an good choice for a wide range of industrial applications. Their automatic operation, low maintenance requirements, and compliance with international standards make them a cost-effective and safe option for controlling fluid flow and preventing backflow.

Main performance specifications

| Test pressure(Mpa) | Nominal pressure(Lb) | |||||||||||

| 150 | 300 | 600 | ||||||||||

| Shell strength test | 3.0 | 7.5 | 15.0 | |||||||||

| Seal test | 2.2 | 5.5 | 11.0 | |||||||||

| Material of valve | WCB(C) | CF8(P) | CF8M(R) | WC6 WC9(V) | ||||||||

| Working temperature | ≤425 | ≤200 | ≤200 | ≤540 | ||||||||

| Applicable medium | Water, steam, oil | Nitric acid | Aectic acid | Water, steam | ||||||||

Implementation Standards

Designing and manufacturing: ANSI B16.34

Structure length: ANSI B16.10

Inspection and testing: API598, API6D

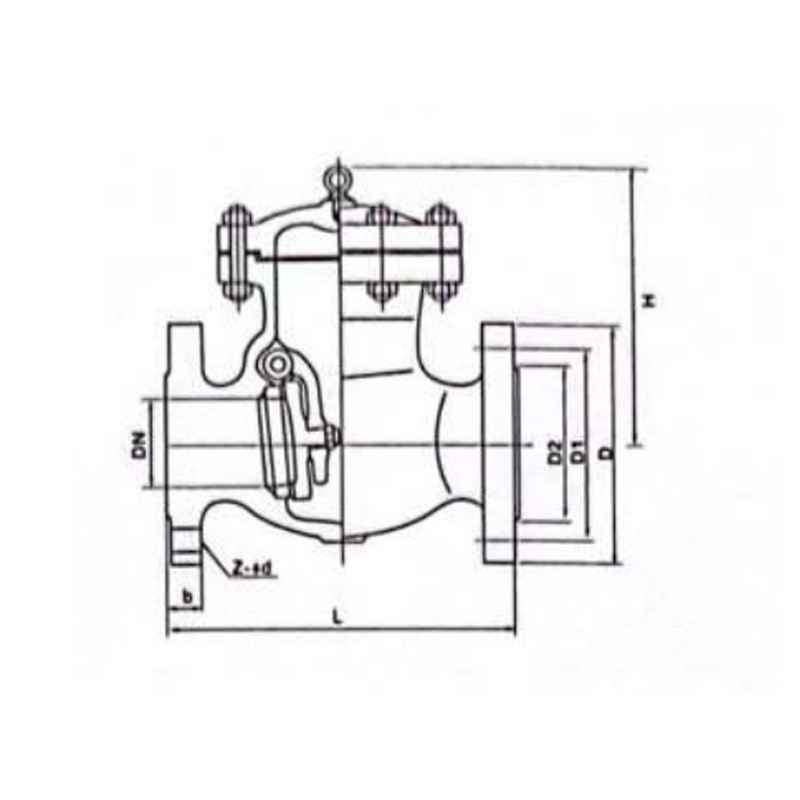

Main dimensions

| Type | Nominal diameter | Unit | Dimensions | |||||||

| ln. | mm | L | D | D1 | D2 | b | Z-φd | H | ||

| 2" | 50 | ln. | 9.00 | 6.00 | 4.75 | 3.62 | 0.75 | 4-0.75 | 6.34 | |

| API 150Lb | mm | 203 | 157 | 120.7 | 92 | 19.5 | 4-19 | 161 | ||

| 21/2" | 65 | ln. | 8.50 | 7.00 | 5.50 | 4.12 | 0.88 | 4-0.75 | 7.08 | |

| mm | 216 | 178 | 139.7 | 105 | 22.5 | 4-19 | 180 | |||

| 3" | 80 | ln. | 9.50 | 7.50 | 6.00 | 5.00 | 0.94 | 4-0.75 | 7.48 | |

| mm | 241 | 190.5 | 152.4 | 127 | 24 | 4-19 | 190 | |||

| 4" | 100 | ln. | 11.50 | 9.00 | 7.50 | 6.19 | 0.94 | 8-0.75 | 8.66 | |

| mm | 292 | 229 | 190.5 | 157.2 | 24 | 8-19 | 220 | |||

| 6" | 150 | ln. | 14.00 | 11.00 | 9.50 | 8.50 | 1.00 | 4-0.88 | 10.12 | |

| mm | 356 | 279 | 241.5 | 216 | 25.5 | 8-22.5 | 257 | |||

| 8" | 200 | ln. | 19.50 | 13.50 | 11.75 | 10.62 | 1.12 | 8-0.88 | 11.50 | |

| mm | 495 | 343 | 298.5 | 270 | 29 | 8-22.5 | 292 | |||

| 10" | 250 | ln. | 24.5 | 16.00 | 14.25 | 12.75 | 1.19 | 12-1.00 | 13.78 | |

| mm | 622 | 406 | 362 | 324 | 30.5 | 12-25 | 350 | |||

| 12" | 300 | ln. | 27.50 | 19.00 | 17.00 | 15.00 | 1.25 | 12-1.00 | 15.6 | |

| mm | 699 | 483 | 432 | 381 | 32 | 12-25 | 30 | |||

With high-quality products, good reputation and high-quality service, our products sell well in more than 20 provinces, cities and autonomous regions in China. We sincerely cooperate with domestic and foreign merchants for win-win cooperation, common development and common prosperity.

In the future, Zhejiang Xiongxiang Valve will continue to uphold the concept of "quality-oriented, customer first", continue to innovate, work together with global partners for win-win results, and create a trustworthy fluid control brand!

-

Understanding how a Flanged Y Strainer connects into a piping system is as important as choosing the right size and screen mesh. Like a Cast...

READ MORE -

Proper installation plays a crucial role in the performance of industrial strainers. A Cast Steel Y Type Strainer and a Flanged Y Strainer a...

READ MORE -

A Cast Steel Y Type Strainer and a Flanged Y Strainer play critical roles in protecting pumps, valves, and other downstream equipment within...

READ MORE -

In industrial settings around the world, operators and engineers encounter real‑world challenges with ANSI Globe Valve installations that ex...

READ MORE -

Choosing the right valve for your industrial system is more than just picking a product off a catalog. When engineers evaluate ANSI Globe Va...

READ MORE -

When planning a new industrial piping project, buyers and engineers often look to SS globe valve manufacturers for quotes and performance sp...

READ MORE

English

English 中文简体

中文简体