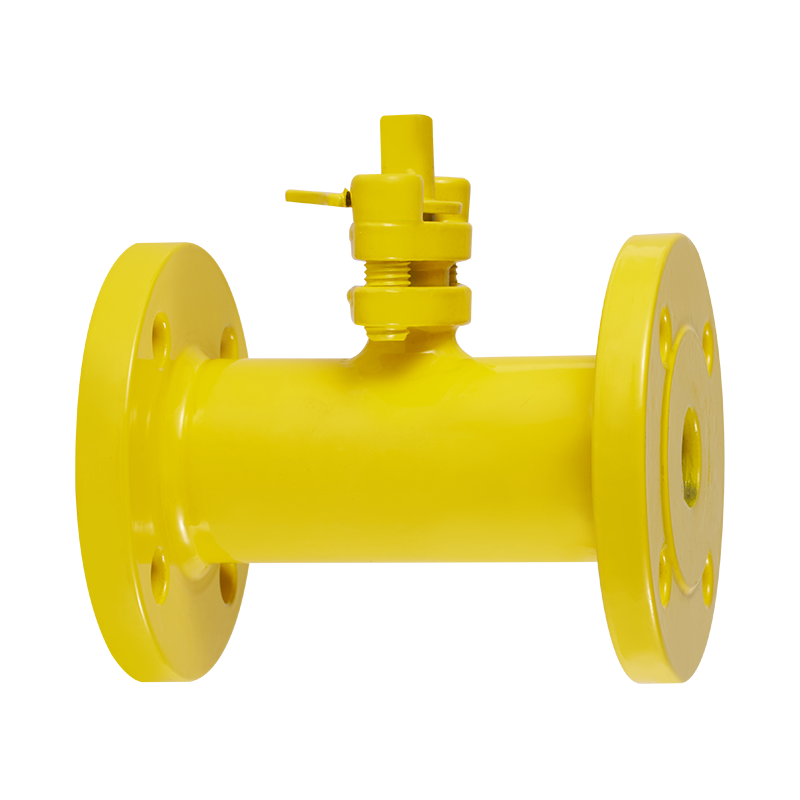

In modern fluid control systems, the cast steel three-way ball valve plays a pivotal role in enhancing operational flexibility and system efficiency. Designed to manage complex flow paths, this type of valve allows users to direct flow between different pipelines or to mix and divert fluids as needed, all with the ease of a single valve unit.

One of the key advantages of the cast steel three-way ball valve lies in its structural integrity. Cast steel provides mechanical strength and resistance to impact, high pressure, and temperature variations. This makes it well-suited for demanding environments, such as oil and gas pipelines, chemical processing plants, and HVAC systems. Its robust construction ensures long service life, reducing the frequency of replacements and contributing to overall system reliability.

Functionally, three-way ball valves offer significant versatility. Available in T-port and L-port configurations, they can be used for a variety of operations, from diverting flow to blending multiple fluid streams. This adaptability helps simplify piping designs, as fewer valves and fittings are needed to accomplish the same functions.

Ease of maintenance is another important factor. The valve's straightforward design—with fewer moving parts and a compact structure—allows for simple inspection and servicing. Combined with its sealing capability, this minimizes the risk of leaks and operational disruptions.

The cast steel three-way ball valve is a highly valuable component for industries requiring reliable, flexible, and efficient fluid control solutions.

What are the Characteristics of Float Operated Ball Valve

Float operated ball valves are a specialized type of control valve used primarily in applications where automatic level regulation is required. Commonly found in water supply systems, cooling towers, and storage tanks, these valves provide dependable operation based on the simple principle of buoyancy.

One defining characteristic of the float operated ball valve is its automatic operation. As the liquid level in a tank rises or falls, a connected float moves correspondingly, mechanically opening or closing the valve. This eliminates the need for external power sources or complex control systems, making float operated valves both energy-efficient and easy to integrate into a wide range of settings.

Another important feature is their reliability in maintaining consistent liquid levels. The design ensures that the valve responds smoothly to changes in fluid level, helping prevent overflows or dry-running conditions. This is particularly valuable in water treatment facilities or process industries where stable liquid levels are crucial for operational efficiency and equipment protection.

Durability is also a strong point of these valves. High-quality float operated ball valves are constructed with corrosion-resistant materials—often stainless steel or high-grade brass—which allows them to perform effectively in challenging environments with varying temperatures and fluid compositions.

In addition, the maintenance requirements of float operated ball valves are generally low. Their simple mechanical structure means fewer components are subject to wear, and routine inspection and cleaning can be performed without major system downtime.

Finally, the versatility of float operated ball valves allows them to be used across many sectors, from residential water storage systems to industrial process tanks. Their ability to deliver automatic, reliable level control with minimal maintenance makes them a practical and valuable choice for managing fluid levels in diverse applications.

English

English 中文简体

中文简体