The Stainless Steel Flange Gate Valve is a widely used component in industrial systems for controlling the flow of liquids and gases. Its robust design, combined with the corrosion resistance of stainless steel, makes it an ideal choice for a variety of applications, including oil and gas, water treatment, and chemical industries. The performance, longevity, and overall effectiveness of a Stainless Steel Flange Gate Valve are significantly influenced by the material selected for its construction. Proper material selection is essential to ensure the valve can withstand environmental stresses and perform under specific conditions.

Stainless steel is typically chosen for its resistance to corrosion, making it suitable for use in both high-pressure and corrosive environments. The alloy composition of stainless steel, which includes chromium, nickel, and molybdenum, contributes to its resistance to rust, pitting, and general wear. For applications that involve exposure to harsh chemicals, high temperatures, or corrosive environments, selecting the correct grade of stainless steel is crucial. For instance, 304 and 316 stainless steels are commonly used in gate valves, with 316 stainless steel offering enhanced resistance to corrosion, particularly in marine and acidic environments.

The material choice also affects the valve's mechanical properties, such as strength, hardness, and ductility. For example, in high-pressure applications, a stronger stainless steel alloy is needed to prevent deformation or failure. Additionally, the valve's sealing surfaces, which are in constant contact with the flow medium, must be made of durable materials to ensure a tight seal, prevent leakage, and reduce wear over time. For these reasons, material selection plays a pivotal role in the performance, durability, and cost-effectiveness of the Stainless Steel Flange Gate Valve.

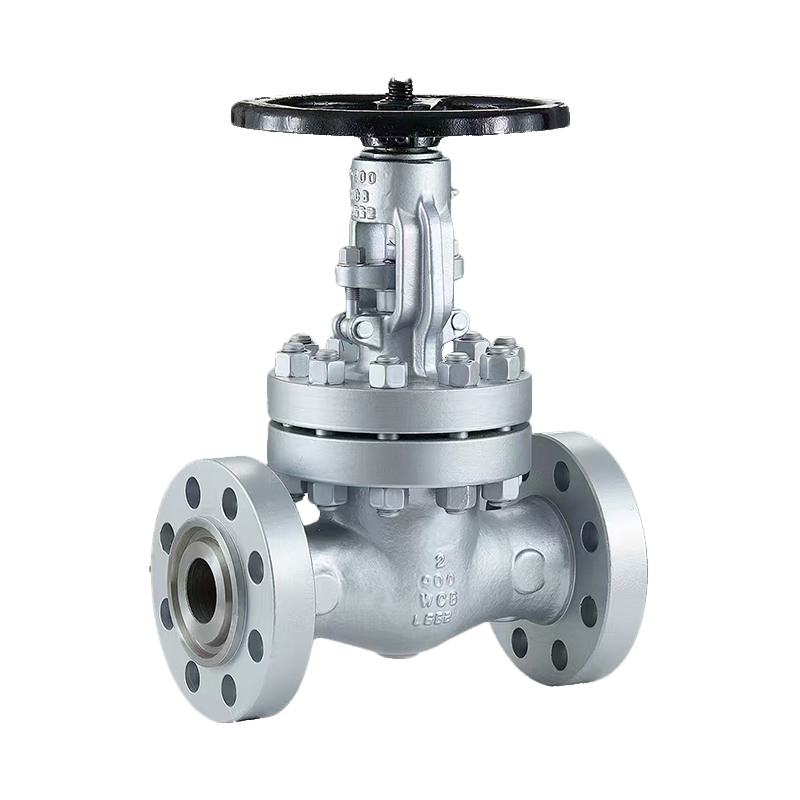

The Heavy Cast Steel Gate Valve is designed to provide reliable, long-term service in high-pressure and high-temperature applications. These valves are often used in industries like power generation, oil and gas, and chemical processing. While heavy cast steel valves are known for their durability and strength, they are not immune to operational issues. Identifying and solving common problems associated with these valves can help maintain system performance, reduce downtime, and prolong the valve's lifespan.

One of the common issues faced by the Heavy Cast Steel Gate Valve is improper sealing. Over time, the sealing surfaces of the valve can wear out due to constant exposure to high-pressure fluids, which can bring about leaks. This problem can be exacerbated if the valve is used in conditions where temperature fluctuations or chemical corrosion are factors. A worn or damaged seat or disc can result in ineffective sealing, allowing fluid to pass through the valve when it should be fully closed.

Solution: Regular inspection and maintenance of the sealing surfaces are essential to prevent leaks. Replacing worn or damaged seats and discs is crucial to restoring the valve's integrity. Additionally, using materials with better resistance to wear and corrosion can significantly extend the service life of the valve.

Another common issue is the build-up of debris or sediment inside the valve, particularly when the valve is used in applications where solid particles are present in the flow medium. This accumulation can obstruct the valve's movement, making it difficult to operate. In some cases, the valve may become completely stuck, preventing the proper regulation of flow.

Solution: Installing filtration systems upstream of the valve can help reduce the amount of debris entering the system. Routine cleaning and maintenance of the valve, including flushing the internal components, are also vital for ensuring smooth operation. Additionally, valves designed with self-cleaning features can help reduce the frequency of maintenance.

A third issue that can arise with Heavy Cast Steel Gate Valves is the development of cracks or fractures in the valve body. These valves are subjected to forces, and over time, the casting material may develop stress fractures, particularly in high-temperature environments or under frequent pressure cycling.

English

English 中文简体

中文简体