The Double Acting Pneumatic Actuator Butterfly Valve is a highly efficient valve commonly used in various industries, including oil and gas, chemical processing, water treatment, and HVAC systems. It integrates a pneumatic actuator with a butterfly valve, enabling precise and automated control of fluid flow.

How it Works:

In a Double Acting Pneumatic Actuator Butterfly Valve, the pneumatic actuator uses compressed air to move the valve stem, which, in turn, rotates the butterfly disk inside the valve body. This rotation opens or closes the valve, regulating the flow of the fluid. The “double acting” mechanism means that the actuator uses air to both open and close the valve, requiring air pressure in both directions to operate. This is different from a single-acting actuator, which uses air to open the valve and a spring mechanism to return it to its closed position.

Advantages:

Fast Response Time: The Double Acting Pneumatic Actuator Butterfly Valve offers a quick response time, which is crucial in applications that require precise and immediate flow control.

Energy Efficiency: Since pneumatic actuators use air to operate, they are more energy-efficient compared to electrically actuated valves, especially in systems with a consistent need for actuation.

Durability and Reliability: This valve combination is known for its durability, even in harsh conditions. The butterfly valve itself is lightweight, easy to maintain, and highly resistant to corrosion, making it suitable for a wide range of chemicals and environments.

Compact Design: Due to its compact and lightweight nature, this valve can be easily installed in tight spaces, making it ideal for systems where space is a constraint.

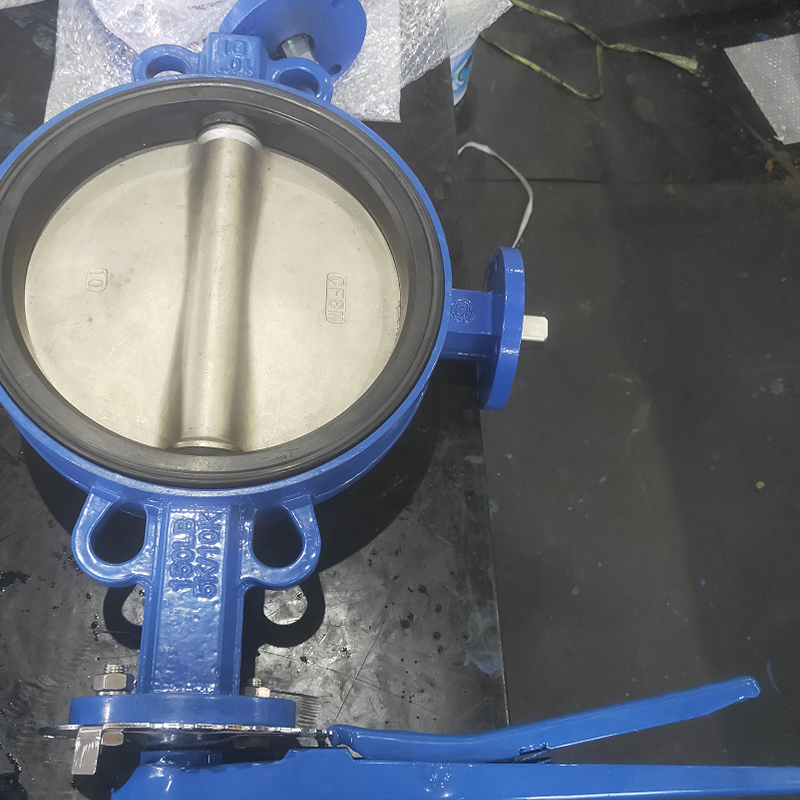

The Butterfly Gate Valve is often used for isolation purposes in systems where the flow needs to be fully turned on or off. These valves are commonly found in water treatment plants, chemical processing industries, and HVAC systems. The Butterfly Gate Valve typically consists of a disc that rotates 90 degrees to allow or block fluid flow. While they serve as shut-off valves, they do not offer the precise flow control of a butterfly valve or the tight shut-off capability of a gate valve. The cost of a Butterfly Gate Valve is influenced by several factors, including size, material, and application requirements.

Factors Affecting the Price:

Size:

The size of the valve is one of the significant factors affecting the price. Larger valves generally cost more than smaller ones, as they require more material and manufacturing effort. For instance, a Butterfly Gate Valve that is 6 inches in diameter will likely be less expensive than one that is 24 inches or larger.

Material:

The material used in the construction of the valve also has a significant impact on its price. Butterfly Gate Valves are often made from materials like cast iron, stainless steel, or bronze. Stainless steel valves tend to be more expensive due to their resistance to corrosion and ability to withstand high temperatures and pressures. For highly corrosive environments or industries dealing with hazardous materials, stainless steel or other alloys may be a necessity, increasing the price.

Pressure Rating:

Valves designed for high-pressure applications require stronger materials and more intricate design features, which can drive up the price. For example, a valve designed for use in a steam system with high-pressure requirements will cost more than a valve intended for a low-pressure water system.

Actuation Type:

The presence of an actuator, such as a manual, electric, or pneumatic actuator, can also influence the price of a Butterfly Gate Valve. Manual valves are typically less expensive than their actuated counterparts, while electric and pneumatic actuators add to the cost of the valve due to their complexity and automation features.

English

English 中文简体

中文简体