The metal seated floating ball valve is often chosen for its ability to handle high-pressure, high-temperature applications in industries such as oil and gas, power generation, and chemical processing. Despite its advantages, this type of valve has a few notable disadvantages that should be considered before installation.

One of the primary drawbacks of the metal seated floating ball valve is the potential for wear and damage to the sealing surfaces. The ball in the valve "floats" and relies on the flow of fluid to maintain contact with the seat, which can bring about abrasion and erosion over time, especially when the valve handles abrasive fluids or operates under high velocities. This wear can compromise the sealing integrity,bring about leaks and reduced performance.

Another disadvantage is the higher torque required to operate the valve. Metal-to-metal seating, while durable, tends to create higher friction between the ball and seat, which requires more force to open or close the valve. This increased torque can necessitate larger actuators or manual effort, making the valve less efficient to operate.

Lastly, metal seated floating ball valves tend to be more expensive than their soft-seated counterparts due to the cost of materials and precision manufacturing. Additionally, their susceptibility to temperature and corrosion can limit their effectiveness in certain applications, requiring additional maintenance and potentially shorter service lives.

The stainless steel float ball valve is a versatile and durable valve designed to regulate fluid levels in tanks, reservoirs, and other fluid storage systems. Installation of this valve requires careful attention to detail to ensure proper functioning, efficiency, and safety.

Before installing the stainless steel float ball valve, it is important to ensure that the pipeline is clean and free of debris. Any particles or contaminants could damage the valve or interfere with its operation. The valve's inlet and outlet connections should be checked to confirm they match the pipe size, and the system should be depressurized to prevent accidents during installation.

The stainless steel float ball valve typically features flanged or threaded connections, which must be securely tightened to prevent leaks. For flanged models, the use of gaskets or seals is essential to ensure a tight fit between the valve and the piping. It is also important to align the valve in such a way that the float operates freely and does not get obstructed during fluid level changes.

The valve should be installed in the correct orientation, as indicated by the manufacturer. Typically, the valve should be positioned vertically to allow the float to move freely in response to fluid level changes. Special care should be taken to check the valve's movement after installation to ensure it operates smoothly and without obstruction.

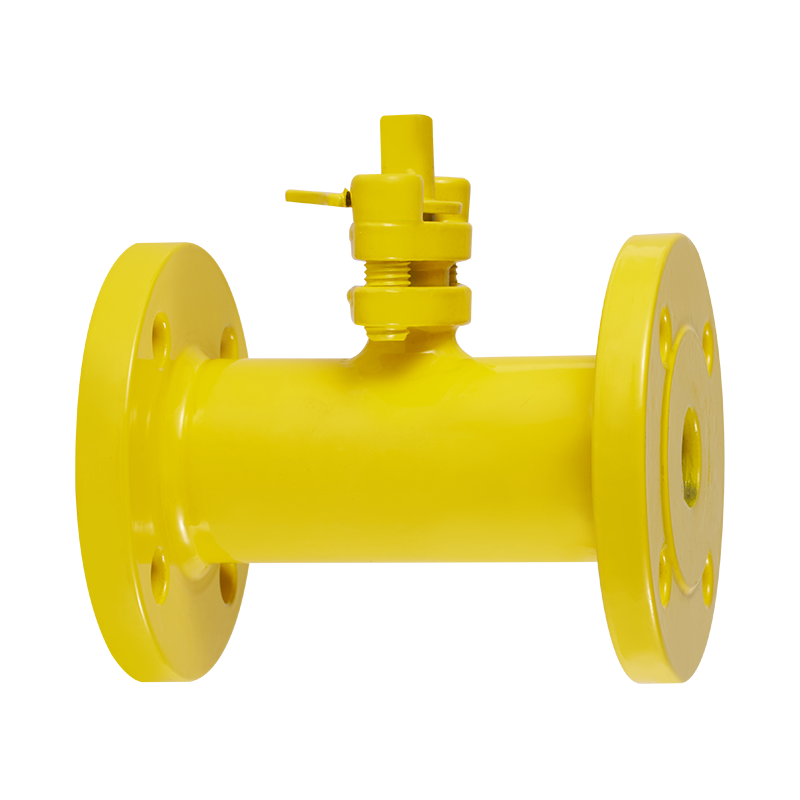

The 3 inch flanged ball valve is a critical component in many industrial systems, providing precise flow control and leak-tight shut-off. Regular maintenance is essential to ensure the valve operates efficiently and reliably, especially in systems exposed to high pressures, temperatures, or corrosive fluids.

The step in maintaining a 3 inch flanged ball valve is regular visual inspections. Check for signs of external damage, such as cracks, corrosion, or rust, that could compromise the valve's integrity. Pay particular attention to the flanged connections to ensure they are properly tightened and secure. Loose connections can bring about leakage or failure of the valve, so periodic re-tightening is recommended.

For valves that see frequent use, it is important to lubricate the valve's stem and ball seat. Over time, friction can cause wear, so lubrication ensures smoother operation and reduces the risk of damage. Be sure to use the appropriate lubricant recommended by the valve manufacturer, as the wrong type of lubricant can cause more harm than good.

English

English 中文简体

中文简体