In today’s competitive industrial landscape, purchasing decisions for valves are no longer based solely on cost and availability. Modern procurement teams are prioritizing material durability, compatibility with automation systems, and lifecycle performance. Among the wide range of valve solutions, two product types are gaining increasing attention: the cast steel ball valve and the industrial ball valve.

Material Trends:

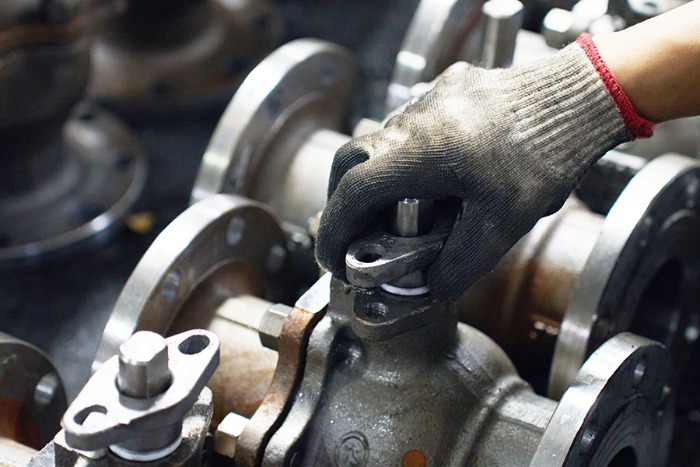

One of the significant developments in recent procurement trends is the emphasis on valve materials. Cast steel has remained a dependable option due to its versatility and cost-efficiency.

Procurement professionals are selecting cast steel ball valves for several reasons:

Mechanical Strength: Ideal for high-pressure applications, cast steel performs well in demanding industrial environments.

Corrosion Resistance: With proper surface treatment, cast steel handles exposure to water, chemicals, and heat effectively.

Flexible Sizing and Design: Casting allows for intricate internal passages and larger diameter bodies, suited for custom system designs.

Compared to other materials such as forged steel or stainless steel, cast steel offers a strong balance between strength and affordability, making it ideal for a wide range of industries—from oil refineries to municipal water systems.

Embracing Automation in Industrial Ball Valves

Automation is no longer optional in large-scale industrial operations. Whether in power plants or chemical factories, the role of the industrial ball valve has evolved from a manual shutoff tool to a dynamic part of the control network.

Buyers are now demanding features such as:

Actuator Integration: Compatibility with pneumatic or electric actuators for remote and precise flow control.

Position Sensors: Providing real-time data on valve status, essential for automated operations.

Low-Torque Operation: Making valve cycling smoother and more energy-efficient.

This push toward automation has made industrial ball valves essential in both new installations and retrofit projects. Valves must now support both mechanical and digital performance expectations—something modern buyers must assess when choosing suppliers.

Applications Driving the Shift

The demand for modernized cast steel ball valves and industrial ball valves is particularly strong in:

Pharmaceutical Processing – Where hygiene and chemical compatibility are critical.

Thermal Power Plants – Requiring high-pressure, high-temperature control.

Desalination and Wastewater – Needing reliable materials that resist scaling and corrosion.

Petrochemical Plants – Where safety and remote control are essential.

In each of these sectors, valve performance directly impacts operational efficiency and compliance with regulatory standards.

Zhejiang Xiongxiang Valve’s Approach to Modern Demands

Our company was founded with a mission to deliver dependable and customized flow control solutions. To meet modern procurement needs, we have adopted several advanced practices:

Material Traceability: Every cast steel component is traceable from raw material to finished product.

Automation-Ready Designs: We offer industrial ball valves preconfigured for actuator installation.

Inspection and Testing: Each valve undergoes strict testing, including shell, sealing, and torque resistance.

Flexible Delivery Options: From small-batch customization to large-volume bulk supply, we accommodate different procurement schedules.

Our valve products are not only used domestically in China but are also exported to clients across Asia, the Middle East, and Europe.

Material science and automation are reshaping how procurement teams choose industrial valves. The cast steel ball valve remains a material favorite due to its resilience and cost-effectiveness, while industrial ball valves are evolving rapidly to meet smart control and performance expectations.

Ready to discuss your next valve project? Contact us today to learn how our team can support your procurement goals with reliable and forward-compatible solutions.

English

English 中文简体

中文简体