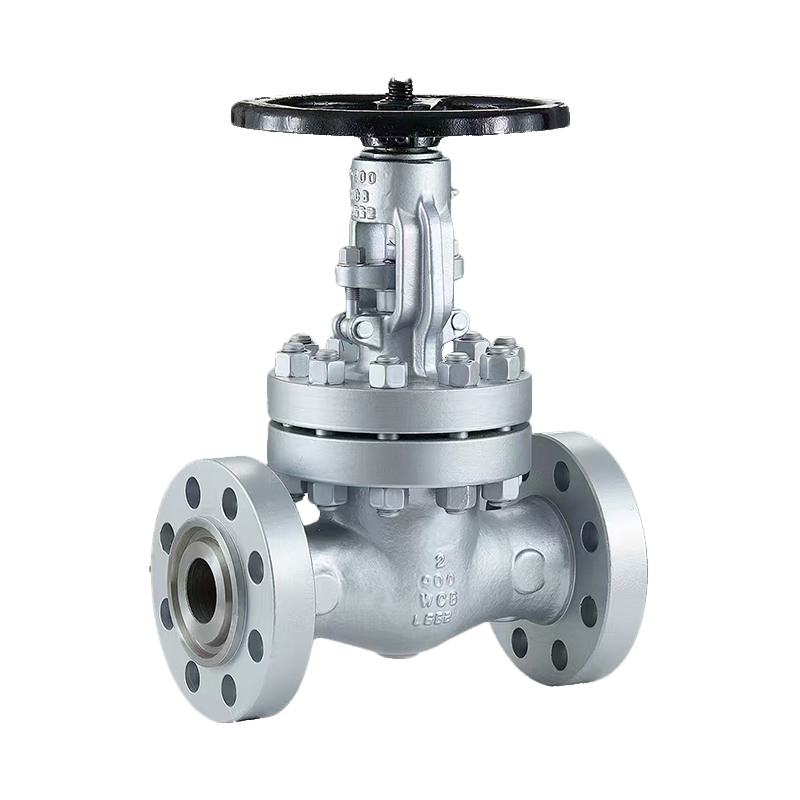

The 2 Inch Carbon Steel Gate Valve is a fundamental component in various fluid control systems, particularly in industries such as oil and gas, water treatment, and manufacturing. While the primary function of this valve is to regulate the flow of liquids or gases through a pipeline, its appearance and design are not just aesthetic considerations but critical factors that contribute to its performance, durability, and ease of use. Proper design ensures the valve operates effectively while meeting the industry's specific needs.

1. Material Selection and Durability

Carbon steel is widely used in the manufacturing of gate valves because of its strength, durability, and cost-effectiveness. For a 2-inch carbon steel gate valve, the material's surface finish is an important design element. Carbon steel is often coated or treated to enhance its corrosion resistance, particularly when used in harsh environments or exposed to corrosive substances. The finish not only impacts the appearance of the valve but also its longevity and maintenance requirements. The valve's body and bonnet should have a smooth, uniform surface free from defects to ensure its sealing surfaces perform.

2. Valve Body and Seat Design

The body of the 2-inch carbon steel gate valve is typically cast or forged, and the design of the valve body is crucial for ensuring the valve's strength and efficient operation. The internal design, particularly the seat and gate, should allow for a tight, leak-free shutoff when the valve is closed. To achieve this, precision machining and finishing of the seat surfaces are necessary, ensuring they are smooth and meet the required tolerances. These design elements must align with industry standards for performance.

3. Actuator and Handwheel Design

Gate valves, including the 2-inch carbon steel gate valve, are typically operated manually using a handwheel or by an actuator for automated control. The actuator and handwheel design must be ergonomically suitable for the system, ensuring ease of use, especially for manual operations in large installations. The valve's appearance is also influenced by its actuator mechanism, which should be sized appropriately for the valve's flow capacity and operating conditions.

Types of Industrial Ball Valves

Industrial ball valves are widely used in various sectors due to their durability, reliability, and versatility in regulating the flow of liquids, gases, and slurries. Ball valves are available in several configurations, each designed for specific applications, pressure ratings, and system requirements. Here are the common types of industrial ball valves:

1. Full Port Ball Valve

The full port ball valve is designed with a bore that matches the diameter of the pipe, allowing for unobstructed flow when the valve is fully open. This type of valve minimizes pressure drops and turbulence, making it ideal for high-flow and high-velocity systems. Full port ball valves are commonly used in systems where maintaining a constant flow rate is essential, such as in the oil and gas, water treatment, and chemical industries.

2. Reduced Port Ball Valve

In contrast to the full port ball valve, the reduced port ball valve has a smaller bore than the pipe, which results in a pressure drop when the valve is open. These valves are often used in systems where the flow rate is not as critical, and the goal is to achieve cost savings without compromising performance. While they are less efficient for high-flow applications, reduced port ball valves are suitable for smaller-scale operations and environments where space and budget constraints exist.

3. Trunnion Mounted Ball Valve

A trunnion mounted ball valve is a type of ball valve designed for high-pressure and high-flow applications. In this valve, the ball is supported by two trunnions (posts), one on the top and one on the bottom, which helps to reduce the force on the valve stem and provides additional stability. Trunnion mounted ball valves are commonly used in large-scale pipelines, especially in the oil and gas, petrochemical, and power generation industries.

English

English 中文简体

中文简体